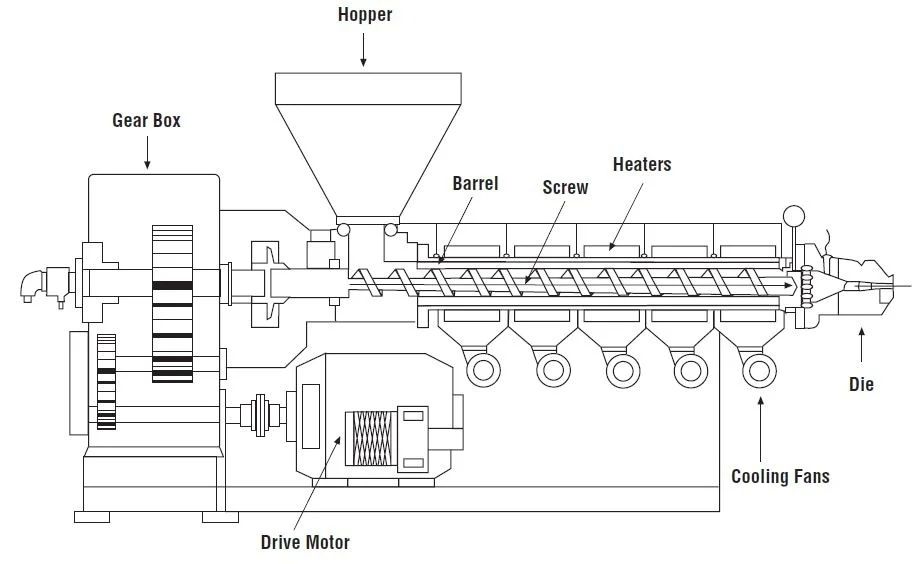

There are different types of extruder machines, including single-screw, twin-screw, and ram extruders. Each is designed to handle specific materials and production requirements. At their core, extruders simplify manufacturing by enabling continuous production of products with uniform quality.

Importance

The role of extruder machines has become vital in modern industry. They:

-

Support mass production by enabling continuous output without interruptions.

-

Enhance material consistency by ensuring uniform mixing and shaping.

-

Reduce waste by optimizing the use of raw materials.

-

Enable product innovation by creating new textures, shapes, and material blends.

-

Promote efficiency in industries where speed and precision directly impact productivity.

Industries most impacted include:

-

Plastics and polymers – for pipes, sheets, films, and molded products.

-

Food processing – for cereals, pasta, and snacks.

-

Pharmaceuticals – for drug delivery systems and capsules.

-

Construction – for building materials like insulation and profiles.

Choosing the right extruder machine matters because the wrong configuration can lead to inefficiency, product defects, or safety risks. This decision affects manufacturers, engineers, operators, and consumers who rely on safe and consistent products.

Recent Updates

The extrusion industry has seen significant changes between 2024 and 2025, with technological advancements shaping production. Key trends include:

-

Energy-efficient extruders (2024): Manufacturers are adopting designs that reduce power consumption to align with sustainability goals.

-

Digital twin integration (2025): Virtual replicas of extrusion systems allow real-time monitoring, predictive maintenance, and process optimization.

-

Advanced screw design (2024–2025): Innovations in screw geometry improve mixing performance and allow processing of complex materials.

-

Biodegradable materials (2025): Extruders are increasingly used for eco-friendly materials such as bioplastics, which are gaining global demand.

-

Automation and AI monitoring (2024–2025): Automated systems adjust extrusion parameters instantly, reducing human error and improving quality.

Reports from 2025 show steady growth in demand for extrusion in packaging, renewable energy materials, and food production, with Asia-Pacific and Europe leading adoption.

Laws or Policies

Extruder machines are regulated under various international and regional standards to ensure safety, environmental compliance, and product quality. Some key examples include:

-

ISO Standards: Cover mechanical safety, testing procedures, and quality benchmarks for extrusion equipment.

-

OSHA Guidelines (United States): Provide rules for operator safety, including machine guarding and emergency procedures.

-

European Union CE Marking: Ensures extruders meet health, safety, and environmental requirements in the EU.

-

Food Safety Regulations: For food extruders, compliance with FDA (U.S.) or EFSA (EU) rules is required to ensure hygienic processing.

-

Environmental regulations: Increasingly, governments are encouraging extruders designed to handle biodegradable materials and minimize carbon emissions.

These policies ensure that extruder machines are not only efficient but also safe for workers and compliant with environmental goals.

Tools and Resources

A range of tools and resources exist to support the proper selection and operation of extruder machines:

-

Extruder design software: Tools such as Polyflow or COMSOL Multiphysics help simulate extrusion processes.

-

Material compatibility charts: These resources guide operators on which extruder is best for specific polymers or food ingredients.

-

Online calculators: Platforms provide extrusion pressure and output calculators for engineers.

-

Training modules: Online learning from engineering organizations helps operators and students understand extrusion principles.

-

Monitoring dashboards: IoT-enabled systems give real-time feedback on extrusion conditions, improving performance tracking.

FAQs

What are the main types of extruder machines?

The main types include single-screw extruders, twin-screw extruders, and ram extruders. Single-screw machines are ideal for simple processes, while twin-screw machines handle complex mixing, and ram extruders are used for specialty applications.

How do I choose the right extruder machine?

Selection depends on factors such as material type, production capacity, desired product shape, and energy efficiency. Engineers often use design software and material charts to guide their decision.

Why are twin-screw extruders popular?

Twin-screw extruders are valued for their ability to handle complex recipes, improve mixing, and produce high-quality outputs consistently. They are widely used in food and plastic processing.

What role does automation play in extrusion today?

Automation allows machines to adjust processing conditions in real time, improving consistency and reducing downtime. It also supports predictive maintenance using data analytics.

Are extruder machines environmentally friendly?

Modern extruders are becoming more eco-friendly by reducing energy use and supporting biodegradable materials. Regulatory policies are pushing manufacturers toward greener designs.

Conclusion

Extruder machines play a vital role in industries ranging from plastics to pharmaceuticals and food production. They provide efficiency, consistency, and innovation in manufacturing. Recent trends show a shift toward energy efficiency, smart automation, and eco-friendly materials, which are shaping the future of extrusion technology.

Understanding regulations, tools, and industry updates helps manufacturers and engineers make informed decisions when choosing the right extruder machine. By aligning with modern innovations and sustainability goals, extruders will continue to be a cornerstone of global production systems.